Basic Info

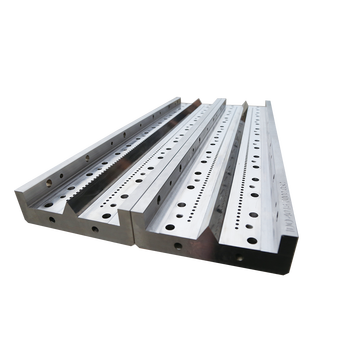

Model No.: 1600mm

Click on the follow link to find out more information: https://www.idotechina.com/melt-blown-nonwovens-fabric-mould-1597447/

Company Info

- Company Name: Wuxi IDO Technology CO.,LTD

- Representative: xu yin

- Product/Service: Stamping die , Washing Machine Drum Assembly Equipment , Dishwasher Tub Assembly Line , stamping tool , metal stamping die , Washing Machine Production Line

- Capital (Million US $): RMB 10 million

- Year Established: 2014

- Total Annual Sales Volume (Million US $): Below US$1 Million

- Export Percentage: 1% - 10%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 4

- No. of R&D Staff: 31 -40 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: Building 4, Qingyun, Xishan science and technology entrepreneurship Park, No.99, Furong Middle Third Road, Xishan District, Wuxi City

- Contact Person: Mr. John.zhou

- Tel: 86-0510-83781892

Premium Related Products

Hot Products

Heavy Duty Industrial Chrome Wire Shelving Rack FactoryFree Standing Adjustable Metal Plant Wire Shelving with Wheels (CJ15045180A5C)Wholesale Price Metal Chrome Slanted Shoe Rack (CJ-B1111)Modern Pentagon Chrome Metal Corner Storage RackModern Adjustable Chrome Metal Office Storage Rack for FileNSF Hospital Drugstore Display Storage RackDIY Bedroom Furniture Steel Wardrobe Closet Rack with T/C Canvas CoverPatented Adjustable Chrome Metal Kitchen Dish Drying Rack, Plate RackDIY 4 Tiers Chrome Metal Bathroom Corner Wire Rack (CJ-C1035)NSF Chrome Plated Metal Wire Restaurant Serving Cart TrolleyAssemble 2 Tiers Chrome Mini Kitchen Spice Wire Rack for HomeNSF Chrome Metal Wire Supermarket Grocery Display Shelf Rack Factory800lbs Adjustable Shelf Steel Wire Metal Shelving Rack with NSF and SGS ApprovalNSF New Metal Perforated Rack for Household (CJ-B1217)4 Tiers Bread Display Rack Shelving Manufacturer (CJ-A1205)Metro Standard Chrome Metal Wire Shelving with NSF and SGS Approval